Offshore rigs face harsh conditions. Wire ropes often fail early. I want to show how to extend rope life and improve uptime.

Offshore drilling wire ropes carry heavy loads under tough conditions. Choosing high-quality, certified ropes ensures safety, longevity, and maximum rig uptime.

Transition paragraph: I remember visiting a rig where worn-out ropes caused delays. It made me realize the importance of selecting the right rope and understanding its features.

What Types of Offshore Drilling Wire Ropes Are Available?

Offshore drilling uses multiple rope types. Each serves a specific function on the rig.

Aulone provides steel and synthetic ropes, including drilling lines, MRTs, crane ropes, winch lines, temporary mooring lines, and lifeboat ropes. Each type is designed for maximum durability and compliance with EN12385.

Steel Wire Ropes for Drilling Lines

Steel ropes are the backbone of offshore operations. They are strong, durable, and designed for constant load.

| Rope Type | Construction | Coating | Use Case | Certification |

|---|---|---|---|---|

| 6X36WS-IWRC | 6-strand galvanized | Lubricated | General purpose | EN12385 |

| 8 Series | 8-strand bright & galvanized | Lubricated | Cranes, winches | EN12385 |

These ropes reduce downtime and maintenance costs. Proper selection depends on the load, frequency, and environmental conditions.

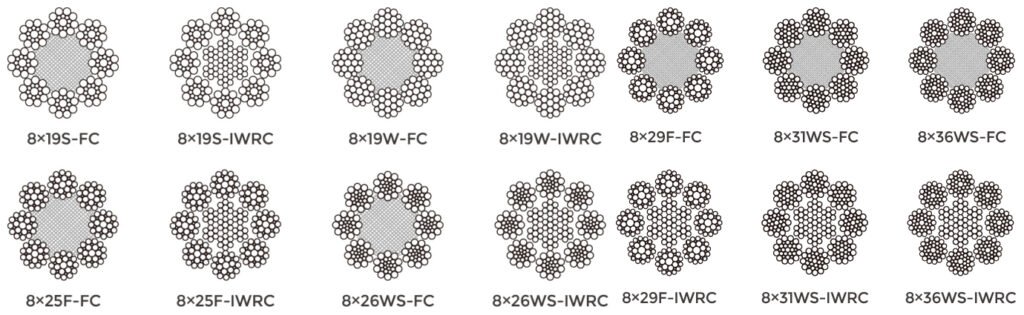

How Construction Affects Rope Life

The core and strand construction determine strength and flexibility. IWRC cores provide higher resistance to crushing. Compacted strands improve wear resistance. Choosing the right construction for each rig application prevents early fatigue.

I often tell colleagues that steel ropes are like the skeleton of the rig—they bear the full weight. Poor construction leads to faster wear and sudden failures. Selecting ropes that match the operational load and rig type is critical.

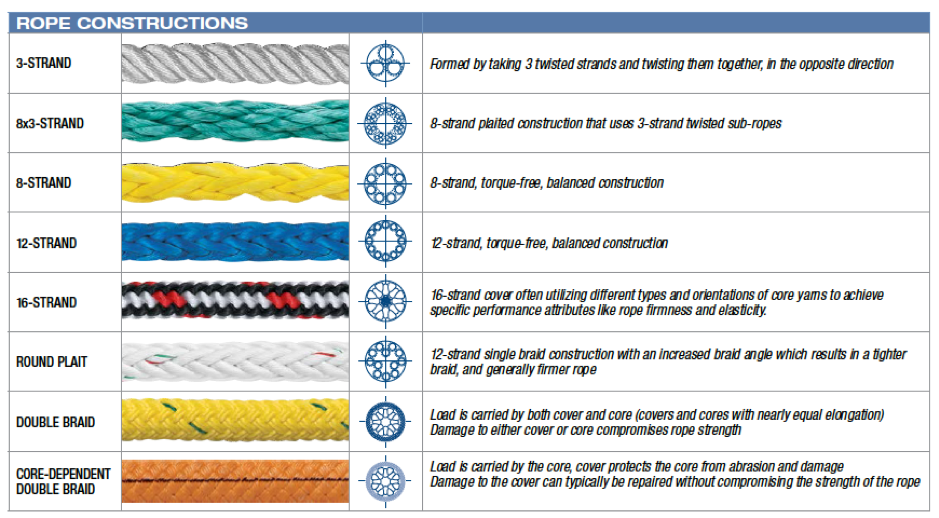

How Do Synthetic Ropes Complement Steel in Offshore Operations?

Synthetic ropes are lighter than steel. They are easier to handle and resist corrosion.

Synthetic ropes, like high-strength fiber lines, reduce weight on the rig, improve safety, and extend service life for non-critical lifting and mooring operations.

Choosing the Right Synthetic Rope

Synthetic ropes are ideal for temporary lines and lifeboat operations.

| Material | Strength | UV Resistance | Application | Certification |

|---|---|---|---|---|

| Polyester | High | Good | Winch lines, temporary mooring | CE, BV |

| HMPE | Very high | Excellent | Lifeboat, crane backup | DNV, ABS |

Synthetic ropes should be inspected regularly. Heat, UV, and abrasion affect performance. Combining synthetic and steel ropes gives balance between strength and flexibility.

Handling and Maintenance of Synthetic Ropes

Synthetic ropes require proper storage away from sunlight. Avoid sharp bends and abrasive surfaces. Regular washing and tension checks help maintain rope strength.

I remember a crew handling synthetic winch lines incorrectly—they left them exposed on deck in sunlight. Within months, the ropes showed fraying and reduced load capacity. Proper storage and maintenance are simple steps but can dramatically extend rope life.

Why EN12385 Certification Matters for Offshore Wire Ropes?

Offshore regulations demand strict safety standards. EN12385 is a key benchmark.

EN12385 ensures wire ropes meet safety, strength, and quality standards. Certified ropes reduce accidents and provide confidence in heavy-lift operations.

Understanding EN12385 Compliance

EN12385 covers rope design, construction, breaking load, and lubrication.

| Certification | Requirement | Benefit |

|---|---|---|

| EN12385 | Load testing, rope construction | Guarantees minimum breaking strength |

| BV / CE | Factory inspection | Confirms consistent manufacturing |

| DNV / ABS | Offshore suitability | Meets rig-specific safety needs |

Using certified ropes reduces downtime and inspection issues. It also ensures liability protection in case of accidents.

Real-World Benefits

On rigs with EN12385-certified ropes, maintenance intervals are predictable. Operators notice fewer sudden failures.

In one offshore project I visited, uncertified ropes failed mid-lift, causing two days of downtime. After switching to EN12385 ropes, the rig reported uninterrupted operations for months. The lesson was clear: certification is not just paperwork—it saves time, money, and lives.

How Can High-Quality Offshore Ropes Extend Rig Uptime?

Downtime costs millions. Wire rope reliability affects overall rig productivity.

Using high-quality steel and synthetic ropes reduces wear, lowers maintenance, and ensures safe, continuous operation for drilling rigs.

Maintenance and Inspection Tips

Regular inspection is critical. Check for broken wires, corrosion, and lubrication levels.

| Inspection Type | Frequency | Key Checks |

|---|---|---|

| Visual | Daily | Broken strands, wear points |

| Magnetic / NDT | Monthly | Internal wire integrity |

| Lubrication | Monthly | Ensure smooth operation |

| Replacement | As needed | Avoid failure under load |

Proper storage, handling, and lubrication also extend rope life. Using Aulone’s engineered ropes ensures consistent performance.

Case Study

A rig using 6X36WS-IWRC ropes noticed 30% less downtime over six months compared to unbranded ropes. Operators reported smoother winch operation and reduced strand wear.

Maintenance records showed fewer lubrication issues, and inspections revealed minimal internal wire damage. This confirmed that investing in high-quality ropes reduces operational risk and improves efficiency.

What Makes Aulone Offshore Ropes Stand Out?

Not all ropes are created equal. Aulone focuses on durability, compliance, and performance.

Aulone offshore ropes combine high tensile strength, customizable options, and certification to meet the demanding offshore environment. Plastic-impregnated and galvanized versions improve lifespan and reliability.

Rope Features

| Feature | Benefit |

|---|---|

| High tensile strength | Handles heavy loads safely |

| EN12385 compliance | Meets strict offshore standards |

| Plastic impregnation | Reduces corrosion |

| Galvanized finish | Increases durability in harsh conditions |

| Custom logo | Brand recognition |

| BV / CE / DNV / ABS | Assures quality and safety |

These features give offshore operators confidence in performance, safety, and return on investment.

Applications Across the Rig

- Drilling lines: Heavy lifting and hoisting

- MRTs: Tension management for marine risers

- Offshore crane ropes: Loading and unloading equipment

- Winch lines: Deck handling

- Temporary mooring lines: Short-term stability

- Lifeboat ropes: Emergency preparedness

I personally check ropes before shipment. Observing proper core lubrication and strand tension gives me confidence that every rope will perform as expected offshore.

Conclusion

High-quality, certified offshore wire ropes ensure safety, reduce maintenance, and maximize rig uptime. Choosing the right rope protects rigs, crews, and investment.